Tufted

DYING AND SPINNING OF MATERIALS

The raw materials that have been weighed out are then sent to the Dye Master and their team, who will at first test small batches to match the colours of the poms we have selected in London. When they have made the match they use the formula they have created to dye the rug materials. After the materials have been dyed, washed and dried, it is then sent back to the weavers who spin the hanks of material into balls. A colour card is also made and given to the weavers with each colour labeled with a number to match the graph.

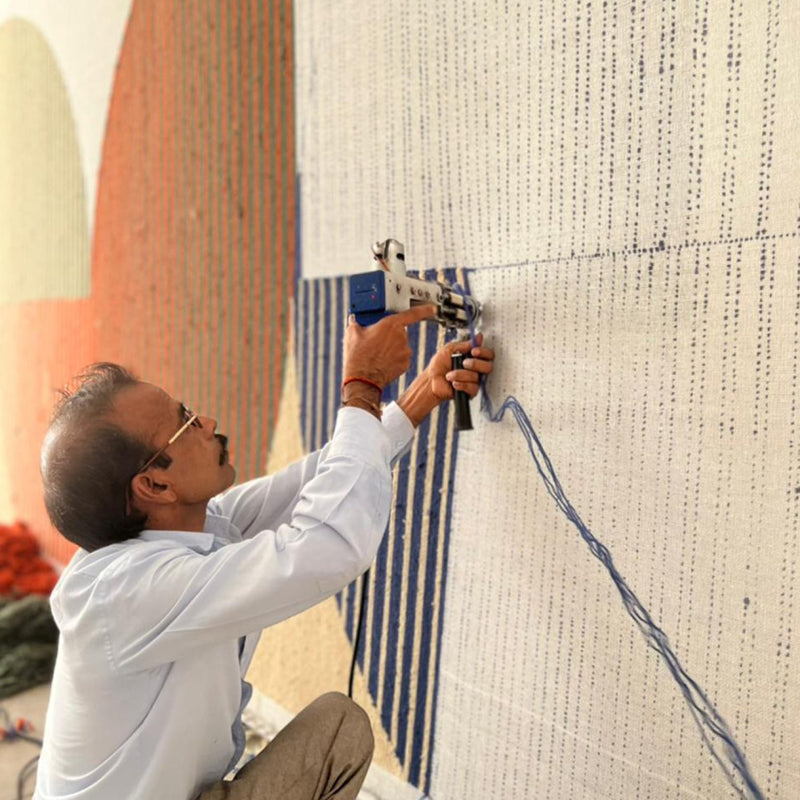

TUFTING THE DESIGN

Canvas is stretched over a large frame which becomes the backing fabric for the wool yarns to be punched through with a tufting gun to create the design. There are two different guns that can be used which creates either a cut pile or loop pile design. The cut pile creates a very clean straight edged finish whereas the loop has a more textural finish. You can also change the pile heights of these by using longer lengths of wool.

BACKING AND CARVING

Once the tufting process is complete, glue is applied in order to hold the yarn in place and then another backing is laid on the back, sticking to the glue.

The carving process entails the cutting down of elements of the rug in order to create alternating pile heights to the rug by using tools such as carving scissors and a yarn shaver. This can add both graphical and textural elements to the design as well as highlighting certain aspects of the overall rug.

TRIMMING AND FINAL DETAILS

With an incredible level of accuracy, the maker will trim around the details of the design to highlight the shapes and forms. A lot of time is taken in this process to ensure total clarity in each section of the rug.

The Rug is then brushed so that all the loose wool fibres come off of the rug and the edges are hand sewn to give a high quality finish. We will then get images sent through to check before the rug is then carefully rolled up and packaged for shipment.

Featured